Tuesday's milling did not happen, despite it being one of the most beautiful days of the year so far. I confirmed on Monday that the crew would be at the beach to set up a couple logs for my buddy and I, but Monday night my buddy bows out as he has a bad flu, then Tuesday morning I check with the crew and they were called away, so no milling Tuesday. But they will be there on Thursday.

So Wednesday night my buddy is still sick, Thursday morning I wake up and the rain is hammering down. I call and confirm that the crew is there to set up a log or two for me, so I load up the van, stop at the coffee shop and head for the beach. By this point the rain has stopped and restarted again, but as I get within a kilometer from the beach my cell rings, it's the crew and saying they blew a hydraulic hose on the loader, so no logs can be set up. What a week! Anyways, I drop by to say hello anyways, and notice that there is at least a half dozen more cherry logs there. So there will be some good milling ahead, if the milling horsehoes ever get their act together again! That will bring this "season's" cherry to about 20 logs, a record for any species for me!

On my other projects, I have definitely violated one of my personal cardinal rules, which is to only work on one project at a time. Too many times I have found myself making tiny progress on multiple projects, seemingly never finishing any of them.

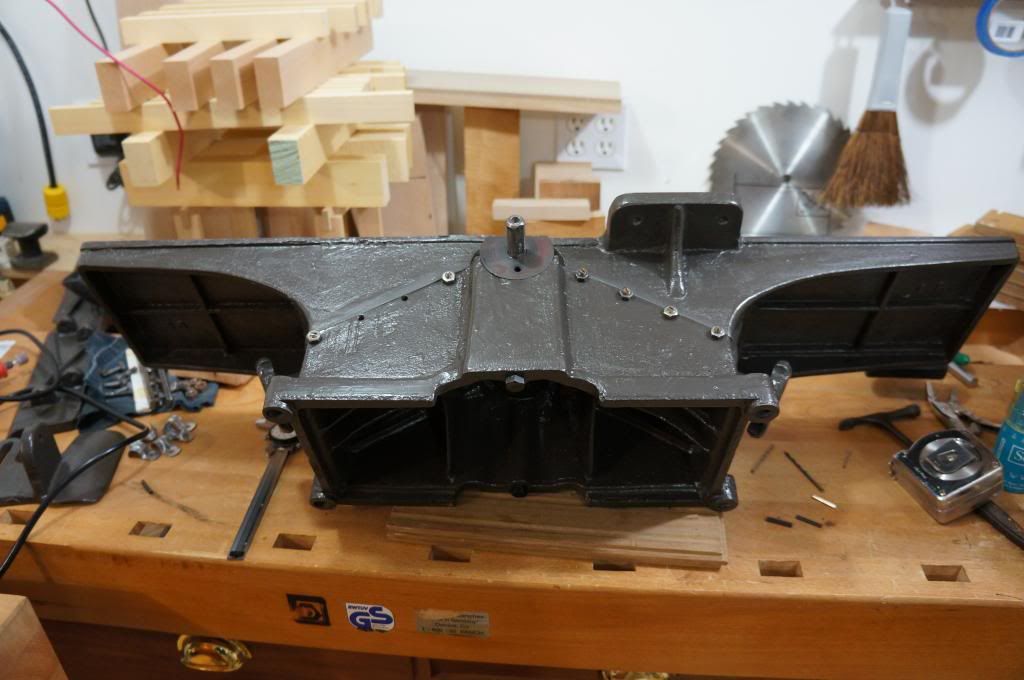

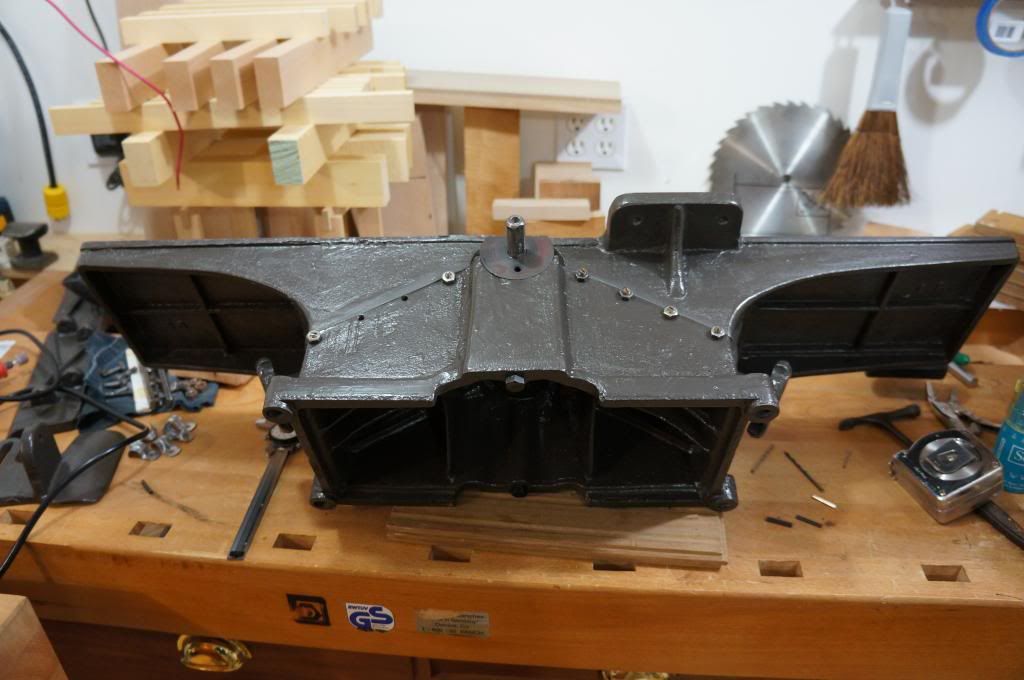

I continue to make tiny progress on the Continental 6" jointer. The knobs for adjusting the height of the infeed and outfeed tables were giving me fits recently. I wound up drilling them and using roll pins to secure them to their shafts. next will be getting the tables level, then I will install the gibs and knives. My enthusiasm for this project has diminished quite a bit, this turned out to be such a coarse machine, I doubt that I will ever use it.

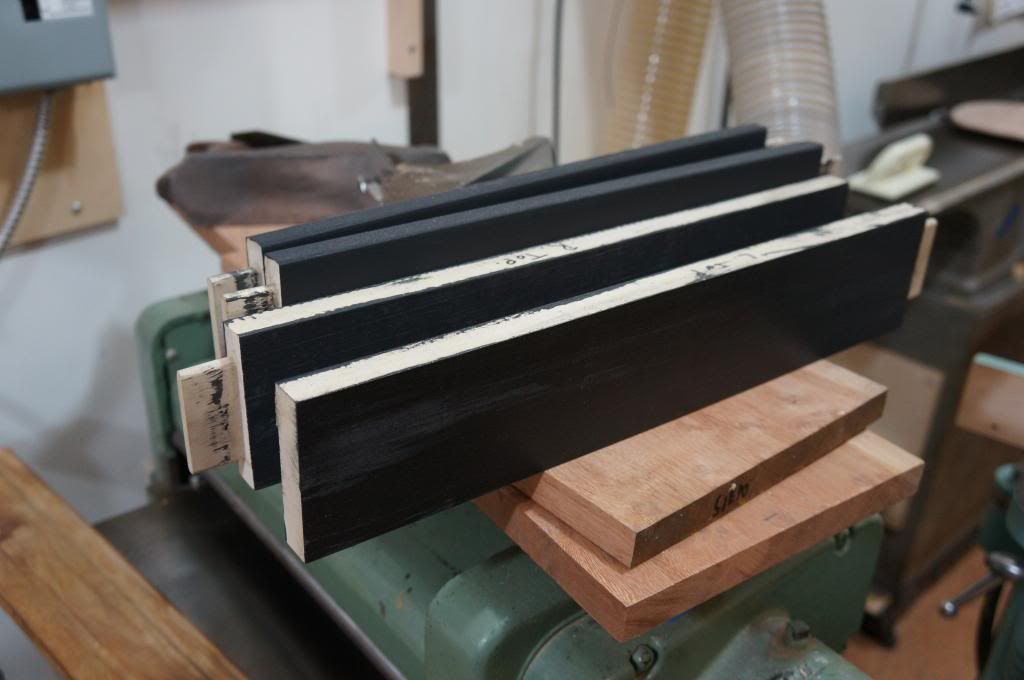

Also rough cut the yellow cedar for the lamp project. I resawed all the pieces to be rift sawn, that way all four sides show nice straight grain lines. I cut a few pieces of alder as well, I'll be using those to start with for practice. I'm letting the wood settle for a while, then I will dimension it once all the movement is done. I am really looking forward to using some of this beautiful old growth material. It is so aromatic in the shop, and the growth rings are incredibly tight, more than 30 per inch. It is a privilige to have such wood.

And I have not given up entirely on my daughter's desk, although it is kind of off again, on again. I did paint it with black milk paint a while ago, and redid a couple pieces that were not right originally. Once I get a topcoat of shellac on I hope to glue it up, and I have a nice slab for the top, I think it is rosewood.

And I am anticipating the arrival of my new

Oneida cyclone

dust collector in a few weeks. I would have prefered a Clearvue, but the Oneida is a 3 HP motor and the Clearvue's are 5 HP and so noisey. My power is quite restricted in my basement shop and I can only provide enough current for a 3 HP motor. So there you are. I have started to make some changes in my shop to accomodate the new system, starting with moving my clamp rack to make room for an old-school manual starter. Love the retro look of this!

And I took all the Manitoba Maple / box elder pieces out of the furnace room the other day as they had dried very nicely there. I think I will sell or trade these small pieces, as I have plenty of this type of wood already.

And of course all the various slabs I have cut over the past few weeks are starting to accumulate against the garage. I really need to get them stacked up properly.

The big bandsaw's mobile base should be done next week. I am having a local machine/welding shop make it up based on a design I saw online. I am really looking forward to getting this big old beast up and running!