Here is a family shot before the kids grew up and went their own way.

I put shellac and a couple coats of oil on the last three, the catalpa, cherry, and elm. The elm and the catalpa had flat lids while the cherry had a thicker lid that I was able to put a small curve into. Annoyingly the cherry lid's grain was much more spectacular before I planed it into a curved shape, I guess just a few degrees off QS and 'poof' went the figure. Ah well, I still like it and all three of these will be gifts in the new year.

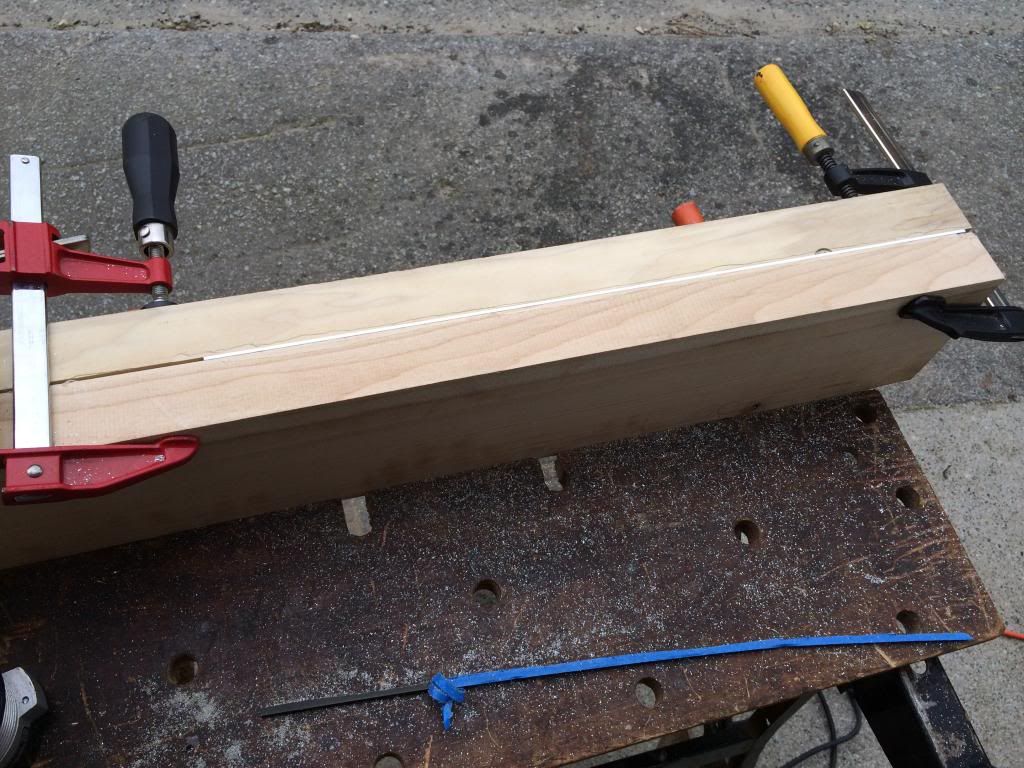

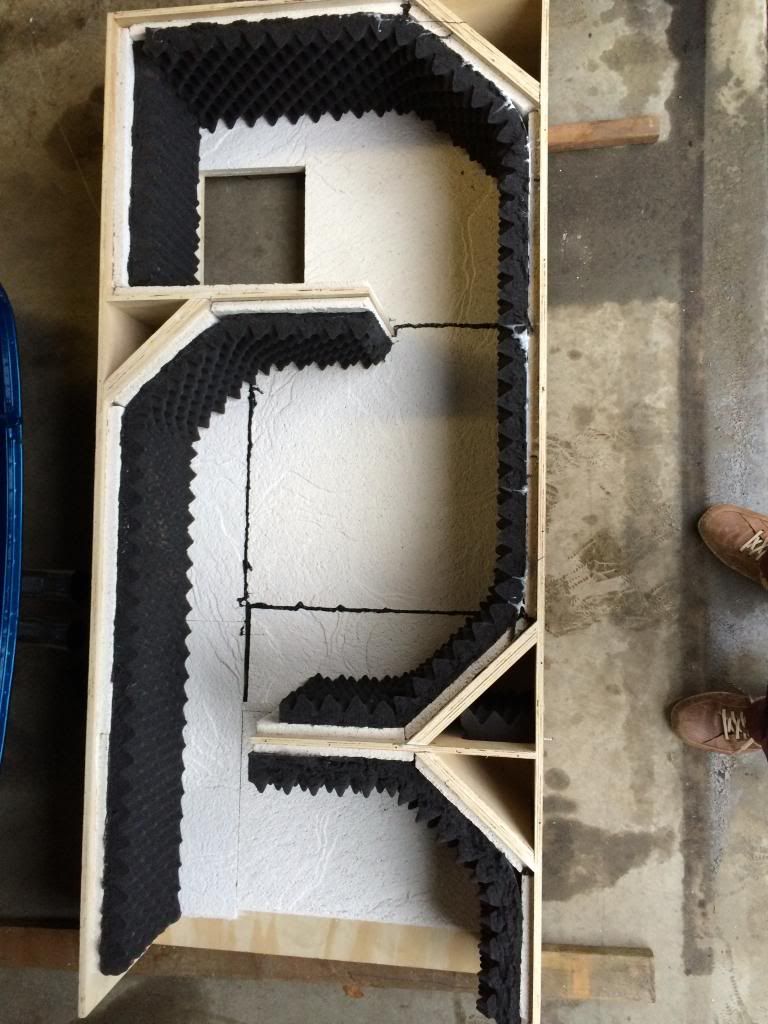

And, the good news is . . . I have actually got back to working on the shoji style lamp and am making some decent progress on it.

In particular I managed to fit the posts and the lower tie ring into the base, which took most of two days. I also started on making the bridle joints on the horizontal slats. Every step that I do I find I need to go back and tweak and refit stuff from previous steps. It is such precise work, I am giving my calipers and feeler gauges a real workout! Once the horizontal and vertical slats are done and in place (please, allow me to dream!) it should look very close to its final look.

And in the setback department, I was outside doing some work on the oak slab table that I am also working on (notwithstanding my sacred vow to only work on one project at a time) when it started to rain. Made a mess of the grain, now I will have to re flatten it probably. Following on in the same vein, there was a wee flood in the basement today that left water puddling on my Hammond Glider table saw. Not impressed, definitely not impressed. Thankfully I caught it early and no real damaage seems to have been done.