Good progress (for me) over the past couple weeks.

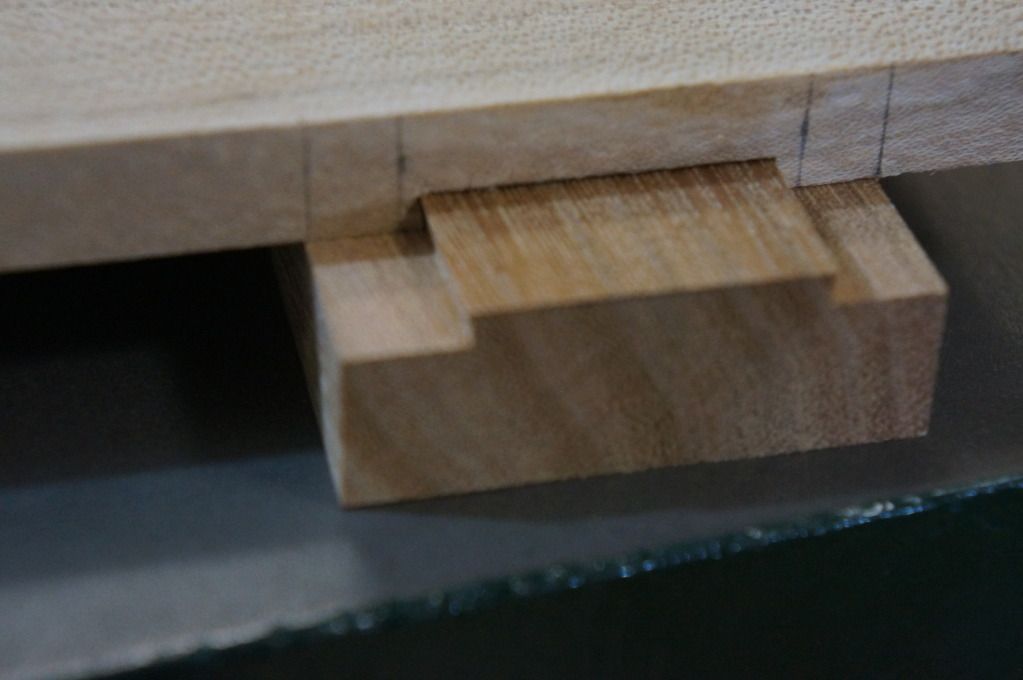

I made the dovetails on the battens for the toolbox lid. Then I fit them in place in dovetailed grooves in the lid that I had previously plowed. First time I had made a sliding dovetail, it worked quite well, the joint is snug.

After a bit of trimming the battens were doing their jobs: They act to hold the lid from falling into the box, and they also act as stop when the lid is slid across the top of the box.

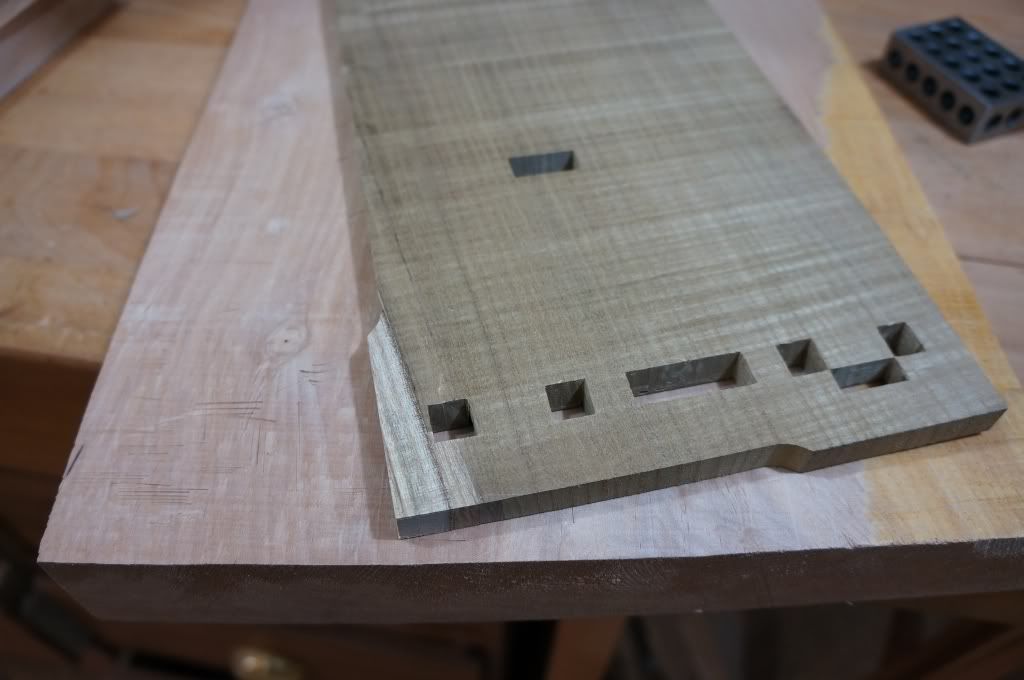

Drilled with a 1/4" bit then squared up a hole right through the middle of each batten and lid. Will add a double wedged pin to hold the batten to the lid in case the sliding dovetail gets loose over time.

Then I will ease some of the sharp edges on the box, plane out a few spots of tearout, and apply some oil to the outside of the box and some shellac to the underside of the lid.

Meanwhile, I also managed to get down to the beach and do some milling with a group of friends earlier in the week. Gorgeous weather!

We cut up three cherry logs that were from flowering cherry trees. This local cherry tends to have mineral streaks in it, although these ones looked pretty good, I find they are more evident once the wood is dry. Also, this local cherry does not have any of the pink in it that lumberyard cherry does.

1 day ago